Table of Contents

Introduction

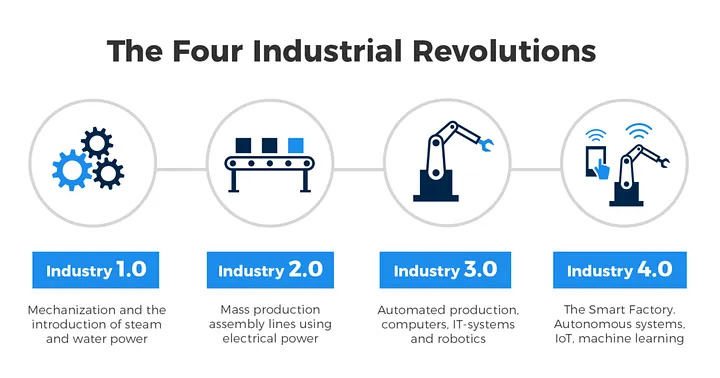

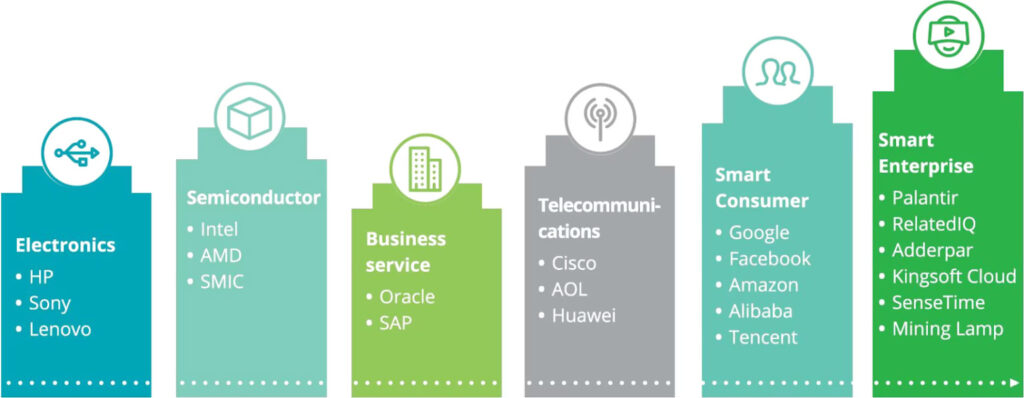

Artificial Intelligence (AI) is part of Industry 4.0, or the Fourth Industrial Revolution, which is transforming how manufacturers produce, enhance, and deliver their products. Companies are incorporating cutting-edge technologies like the Internet of Things (IoT), cloud computing, analytics, and artificial intelligence (AI) with machine learning (ML) into their manufacturing environments and operational processes.

This evolution represents the contemporary wave of automation and digital innovation within manufacturing technologies. It encompasses the adoption of sophisticated technologies in the manufacturing sequence, including:

- Internet of Things (IoT)

- Artificial Intelligence (AI) and Machine Learning (ML)

- Robotics

- Big Data Analytics

AI revolutionizes manufacturing by streamlining operations, reducing costs, & improving quality. Integrating machine learning, NLP, robotics, & analytics creates smart manufacturing, minimizing downtime & waste.

AI integrates machine learning, natural language processing, robotics, and data analytics to create smart manufacturing.

Major companies like GE & Siemens successfully implement AI, driving progress towards efficient, sustainable, & innovative practices. AI in manufacturing introduces machines that learn, adapt, & make decisions based on real-time data, redefining the potential of manufacturing operations, & driving the shift towards Industry 4.0.

The Role of AI in Manufacturing

How AI Differs from Traditional Automation

- Traditional automation systems operate based on fixed algorithms and rules

- AI-driven systems learn from data, recognize patterns, and make informed decisions

- AI-driven systems can optimize operations dynamically and offer personalized solutions to complex challenges

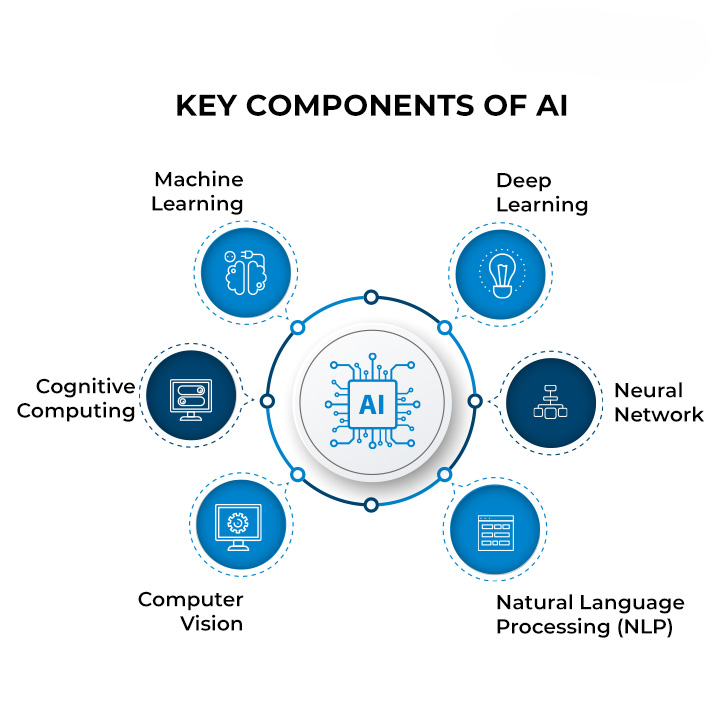

Overview of AI Technologies Impacting Manufacturing

Several AI technologies have emerged as game-changers in the manufacturing sector, including:

- Machine Learning: Machine learning algorithms analyze vast datasets to predict outcomes, optimize processes, and detect anomalies. In manufacturing, this can translate to predictive maintenance, quality control, and demand forecasting.

- Computer Vision: Computer vision enables machines to interpret and act upon visual data. In the manufacturing context, this technology is used for quality inspection, where AI systems can identify defects with higher accuracy and speed than human inspectors.

- Robotics: AI-powered robotics are capable of performing complex tasks that require adaptability and precision. These robots can work alongside humans to enhance productivity and safety, taking on hazardous tasks or those that require repetitive motion.

- Natural Language Processing (NLP): While less prominent than machine learning or robotics, NLP plays a crucial role in facilitating human-machine interaction. It allows workers to interact with machines using natural language, simplifying the control and monitoring of AI-driven systems.

The shift towards smart manufacturing and Industry 4.0.

- Smart manufacturing integrates AI, IoT, big data analytics, and cybersecurity to create an intelligent manufacturing ecosystem.

- The main goal of smart manufacturing is to achieve flexible, efficient, and self-optimizing production processes that can adapt to market changes in real time.

- Industry 4.0 envisions factories where machines and systems communicate seamlessly, workflows are optimized dynamically, and decision-making is data-driven.

By leveraging AI, companies can anticipate and mitigate potential issues before they arise, adapt to changing consumer demands with agility, and unlock new opportunities for innovation.

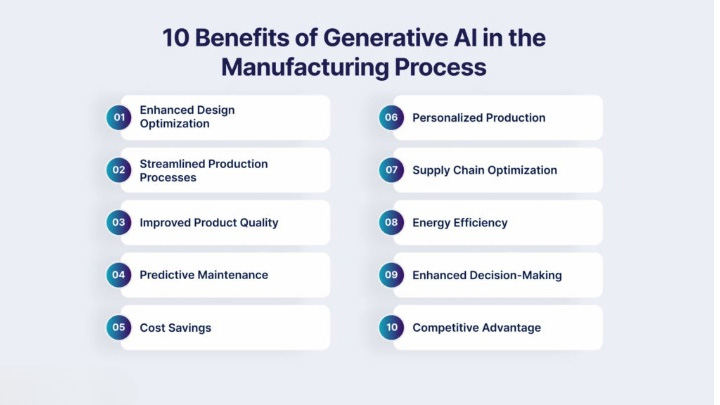

Benefits of AI in Manufacturing

The integration of Artificial Intelligence (AI) into the manufacturing sector has ushered in a new era of operational excellence, product quality, and innovation.

AI stands distinct from traditional automation by its ability to learn from data, predict outcomes, and make decisions with minimal human intervention. This transformative technology offers a plethora of benefits that significantly enhance manufacturing processes:

Increased Efficiency

- AI-powered chatbots provide 24/7 customer support, improving customer satisfaction and loyalty.

- They can handle a large volume of inquiries simultaneously, freeing human agents to focus on complex tasks requiring a human touch.

Improved Quality Control

- AI systems in manufacturing can inspect and analyze products at a level of detail far beyond human capability.

- These systems can detect defects or deviations from the standard quality in real time, reducing the rate of errors and ensuring that only high-quality products reach the market.

- This not only saves costs associated with rework and recalls but also strengthens the brand’s reputation.

Enhanced Supply Chain Management

- AI-driven analytics provide unprecedented insights into supply chain dynamics

- Accurate demand forecasting and inventory management can be achieved by analyzing market trends and consumer behavior

- AI can predict demand with high accuracy, helping manufacturers adjust their production schedules and inventory levels, leading to optimized supply chain efficiency.

Worker Safety and Ergonomics

- AI-powered monitoring systems can identify safety hazards and unhealthy working conditions in real-time.

- Alerts can be sent to managers and workers to take immediate action to prevent accidents and injuries.

- A proactive approach to safety enhances worker well-being and contributes to a more productive and harmonious workplace.

By increasing efficiency, improving quality control, enhancing supply chain management, prioritizing worker safety, and enabling customization and innovation, AI is not just transforming manufacturing operations—it’s redefining what’s possible in the industry.

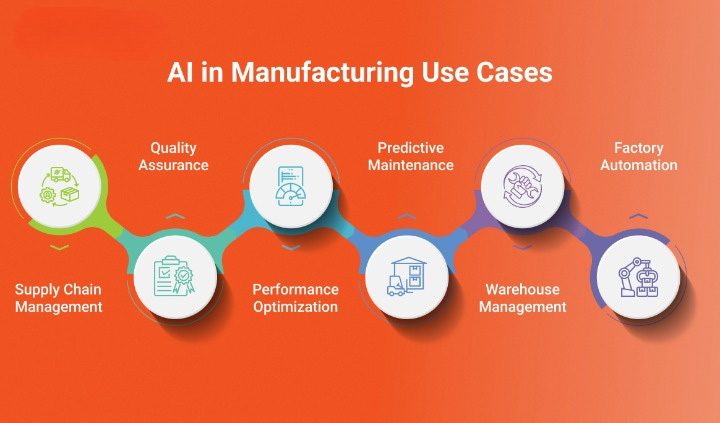

Use Cases of AI in Manufacturing

Artificial Intelligence (AI) is revolutionizing the manufacturing industry by introducing smarter ways to maintain machinery, inspect quality, manage supply chains, and even conserve energy. Here’s a deeper look into how AI is being utilized across various facets of manufacturing:

Predictive Maintenance

- Predictive maintenance is a highly impactful use case of AI in manufacturing.

- AI algorithms can analyze data from sensors and machine logs to predict equipment failures before they happen.

- This foresight allows for maintenance to be scheduled at the most opportune times, minimizing downtime and extending the lifespan of machinery.

Quality Inspection

- AI-powered vision systems have transformed quality inspection processes in manufacturing.

- These systems use computer vision to detect defects, variations, and non-compliance issues in real-time.

- AI vision systems are highly precise and consistent, outperforming human capabilities and reducing waste and rework costs.

Robotics and Automation

- AI-powered robots can perform complex manufacturing tasks with high precision and flexibility

- They can learn and adapt to varying conditions and tasks, improving their performance over time

- These robots are especially valuable in hazardous and high-precision environments, such as handling toxic substances or assembling intricate electronic components.

Supply Chain Optimization

- AI algorithms are being applied to streamline supply chain management, making it more efficient and responsive.

- By analyzing patterns and predicting trends, AI can optimize inventory levels, reduce lead times, and improve order accuracy.

- This use of AI not only ensures that materials are available when needed but also helps mitigate the impact of supply chain disruptions by identifying risks and suggesting alternative strategies.

Energy Management

- AI systems can analyze energy consumption patterns in manufacturing facilities to identify inefficiencies and opportunities for reducing energy waste.

- By optimizing energy use, AI contributes to more sustainable manufacturing practices and significant cost savings.

- AI can dynamically adjust the operation of HVAC systems based on real-time data, ensuring optimal energy use at all times.

These use cases of AI in manufacturing not only showcase the technology’s versatility in addressing a wide range of challenges but also highlight the significant value it brings in terms of efficiency, cost savings, quality improvement, and sustainability.

Real-World Examples of AI in Manufacturing

The implementation of Artificial Intelligence (AI) in manufacturing is not just theoretical but has been successfully applied across various industries, demonstrating tangible benefits and groundbreaking advancements.

Here are real-world examples of AI applications in the automotive, electronics, pharmaceuticals, and food and beverage sectors:

General Manufacturing Industry

Siemens

- Siemens is a prominent global player in electronics and electrical engineering, with operations in industry, energy, and healthcare sectors.

- The company has a rich history of innovation and is at the forefront of incorporating artificial intelligence (AI) into its operations, products, and services.

- SiemensAI is a cutting-edge technology that optimizes tool placements within machine tools, resulting in up to 10% reduction in production times without requiring any new hardware.

General Electric

- General Electric Company (GE) was founded in 1892 and is headquartered in Boston, USA.

- The company has several divisions, including aerospace, power, renewable energy, digital industry, additive manufacturing, and venture capital and finance.

- GE’s Research team is working on developing and demonstrating AI technologies that enable industrial machines to learn and act creatively on the fly like humans.

Automotive Industry

Tesla

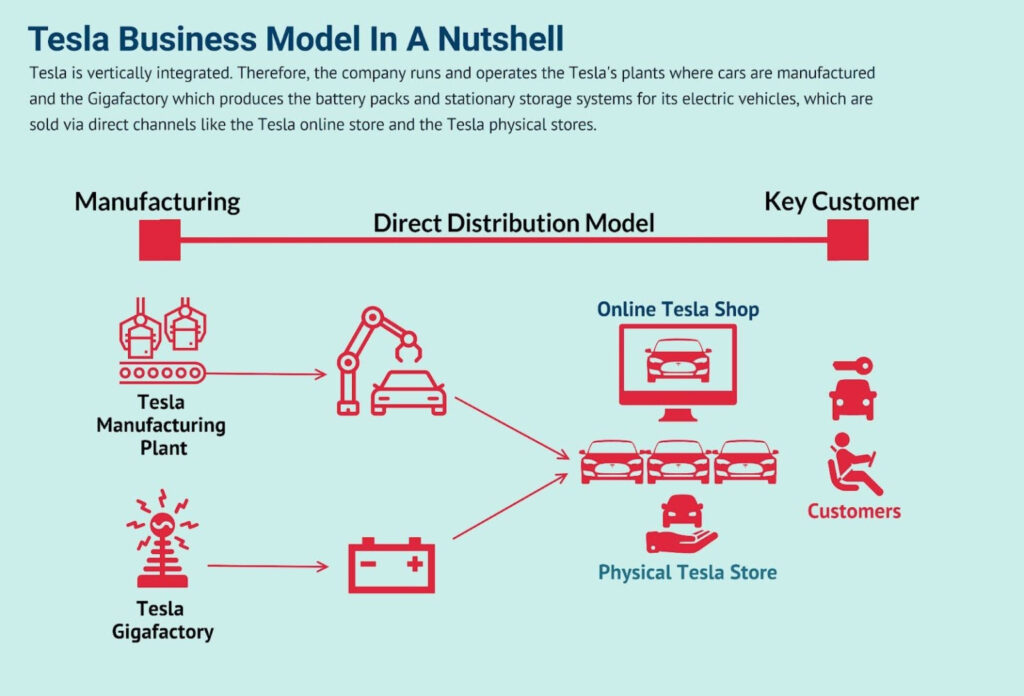

Tesla, a leader in electric vehicles and autonomous driving technology, heavily integrates AI into its manufacturing processes and product offerings.

- In its factories, AI-driven robots and smart systems optimize the assembly lines, enhancing efficiency and precision.

- Tesla’s Autopilot system, an advanced driver-assistance system, uses AI to enable vehicles to navigate with minimal human intervention, showcasing the potential of AI in autonomous vehicle technology.

BMW

BMW employs AI in its production facilities to improve quality control and streamline operations.

- For example, AI-powered optical inspection systems analyze images of vehicles during production to detect any deviations or defects, ensuring high-quality outputs.

- BMW also uses AI to predict maintenance needs for its manufacturing equipment, minimizing downtime.

Electronics Manufacturing

Samsung

- Samsung employs AI for quality control in electronics manufacturing, specifically for identifying defects in Printed Circuit Boards (PCBs) through image analysis.

- Samsung Electronics is planning to fully automate its semiconductor factories by 2030, with “smart sensors” set to control the manufacturing process, according to South Korean media reports.

- The world’s largest maker of memory chips aims to create an “artificial intelligence fab” that operates without human labor, the reports said. The ground-breaking project is reportedly already underway, the same reports said.

Foxconn

- Foxconn, a major manufacturer of electronics, is using AI-driven robots to automate complex manufacturing tasks, enhancing efficiency and reducing reliance on human labor.

Pharmaceuticals

Pfizer

- Pfizer uses AI for drug discovery and manufacturing. AI speeds up candidate identification and optimizes production lines for efficiency and quality.

Roche

- Roche uses AI to improve diagnostics in pharmaceutical manufacturing. AI analyzes test results, ensuring products meet health and safety standards. It is also used for predictive maintenance, reducing downtime, and maintaining consistent quality.

Food and Beverage

Coca-Cola

- Coca-Cola leverages AI for product sorting and quality control, as well as market analysis and consumer behavior prediction.

Nestle

- Nestle uses AI for product sorting, packaging, and quality control. It also employs AI for demand forecasting and supply chain optimization to reduce waste.

These examples underscore the versatility and impact of AI across different sectors of manufacturing. By improving efficiency, quality, and innovation, AI is not only transforming manufacturing processes but also enabling companies to meet the evolving demands of consumers and markets more effectively.

Challenges and Considerations

The integration of Artificial Intelligence (AI) in manufacturing, while offering numerous benefits, also presents several challenges and considerations that must be addressed to harness its full potential effectively.

Integration Complexity

- Upfront costs and the complexity of integration can make it challenging to integrate AI into existing manufacturing systems.

- Extensive modifications or upgrades may be required to make legacy systems compatible with the latest AI technologies.

Data Privacy and Security

- With the use of AI, manufacturing firms can improve their operations and increase efficiency, but they must also be aware of the potential risks related to data privacy and security.

- Implementing cybersecurity measures such as encryption, access control, and network segmentation can help protect sensitive data from cyberattacks.

- Regular employee training and awareness programs can help educate staff about the importance of data protection and how to identify and prevent cyber threats in the manufacturing industry.

Workforce Impact

- AI can take over repetitive and hazardous tasks in manufacturing, reducing the risk of injury and increasing efficiency.

- Workforce planning and investment in training programs can help prepare employees for higher-value roles and prevent job displacement due to automation.

Ethical and Regulatory Implications

- Manufacturers should aim to eliminate algorithmic bias by creating diverse teams to develop AI and regularly auditing their AI models.

- Transparency in AI decision-making can be achieved by providing clear explanations of how decisions are made and ensuring individuals have the right to contest decisions made by AI systems.

Future Trends and Predictions

The landscape of AI in manufacturing is rapidly evolving, driven by continuous advancements in technology and changing industry needs.

Evolving Landscape of AI in Manufacturing

- AI will enable manufacturers to make more informed decisions by analyzing data in real time and identifying patterns that may not be visible to humans.

- With AI’s assistance, manufacturers will be able to optimize their processes, reduce waste, and improve product quality while also enhancing customer experience.

Emerging Technologies and Their Potential Impact

- The convergence of technologies such as digital twins, AR, IoT, and AI will create new opportunities for enhancing manufacturing processes.

- By leveraging these technologies, businesses can create immersive and data-rich environments that can be used for design, training, and other applications.

Predictions for the Future of Manufacturing in an AI-driven World

- AI will revolutionize manufacturing by enabling highly flexible, efficient, and sustainable operations.

- Mass personalization of products will become possible through the use of AI technology.

- Collaboration between humans and robots will enhance productivity and creativity in manufacturing.

Conclusion

The integration of AI into manufacturing heralds a transformative era for the industry. While challenges exist, particularly in terms of integration complexity, data privacy, workforce impact, and ethical considerations, the benefits and future possibilities of AI in manufacturing are immense.

By addressing these challenges head-on and leveraging emerging technologies, the manufacturing sector can look forward to a future where AI not only optimizes production but also drives innovation, sustainability, and enhanced global competitiveness.

As we move forward, the synergy between humans and AI will redefine what’s possible in manufacturing, setting the stage for a more efficient, creative, and sustainable industry.

Deepak Wadhwani has over 20 years experience in software/wireless technologies. He has worked with Fortune 500 companies including Intuit, ESRI, Qualcomm, Sprint, Verizon, Vodafone, Nortel, Microsoft and Oracle in over 60 countries. Deepak has worked on Internet marketing projects in San Diego, Los Angeles, Orange Country, Denver, Nashville, Kansas City, New York, San Francisco and Huntsville. Deepak has been a founder of technology Startups for one of the first Cityguides, yellow pages online and web based enterprise solutions. He is an internet marketing and technology expert & co-founder for a San Diego Internet marketing company.