Table of Contents

Introduction

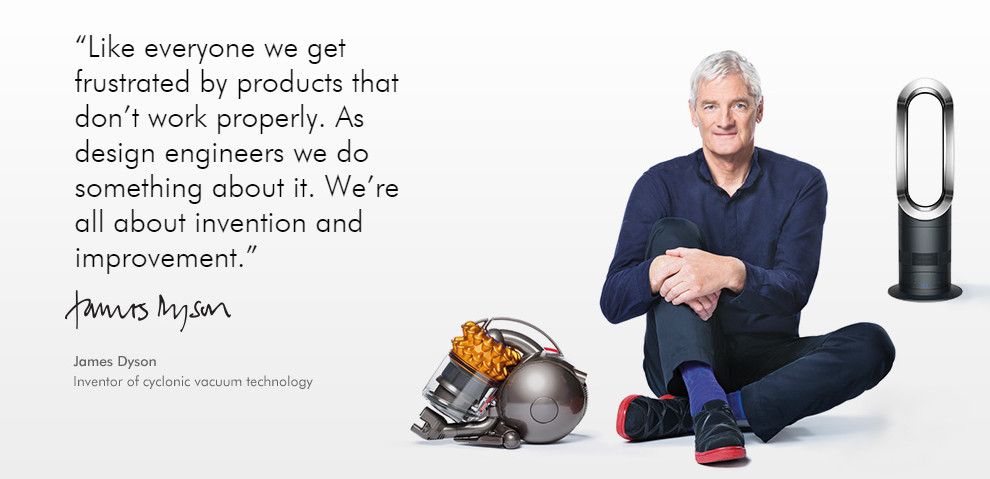

- At its heart, Dyson is built on a simple yet profound idea: solve real-world problems through better design.

- Whether it’s reengineering airflows, creating powerful digital motors, or redefining hair care, every Dyson product is a result of rigorous experimentation, often backed by thousands of prototypes and years of development.

Key Statistics

- Dyson failed 5126 times, to be exact, before finalizing a vacuum cleaner prototype

- Dyson employs over 14,000 people and operates in over 65 countries

- Dyson has a total of 3536 patents globally, out of which 1713 have been granted

- Dyson plans to double its product range by 2025 through a £2.7 billion investment

- Dyson’s first proprietary battery manufacturing plant in Singapore will be fully operational by 2025, producing advanced battery cells for future products

History of Dyson

James Dyson was born in 1947 in Cromer, Norfolk, England. In the 1970s, while struggling with clogs in traditional vacuum bags, he was inspired by industrial cyclones from sawmills.

- Working in his own workshop, he aimed to apply cyclone technology to household vacuum cleaners—leading to over 5,000 failed prototypes over five years before finally producing the G-Force cleaner in 1983

- The G‑Force launched in Japan—no U.K. brands backed it—proving hugely successful and bringing home enough royalties for Dyson to found Dyson Ltd in 1991.

- By 1993 he introduced the DC01 vacuum from his newly opened research centre and factory in the Cotswolds, featuring the first dual cyclone system that maintained suction fully.

- Dyson’s success soared—he turned away traditional vacuum bag suppliers, shifted manufacturing toward Singapore, and built global R&D hubs.

- Strategic investments landed in robotics labs at Imperial College, engineering education via Dyson Institute, and cutting-edge battery and AI research.

Thus, Dyson evolved from innovative start-up to technology leader—grounded in hands-on engineering and rooted deep in product excellence.

Dyson’s Design Philosophy & Innovation Centers

Core Philosophy

At Dyson, design means solving real problems—stripping away excess until each feature serves a clear purpose.

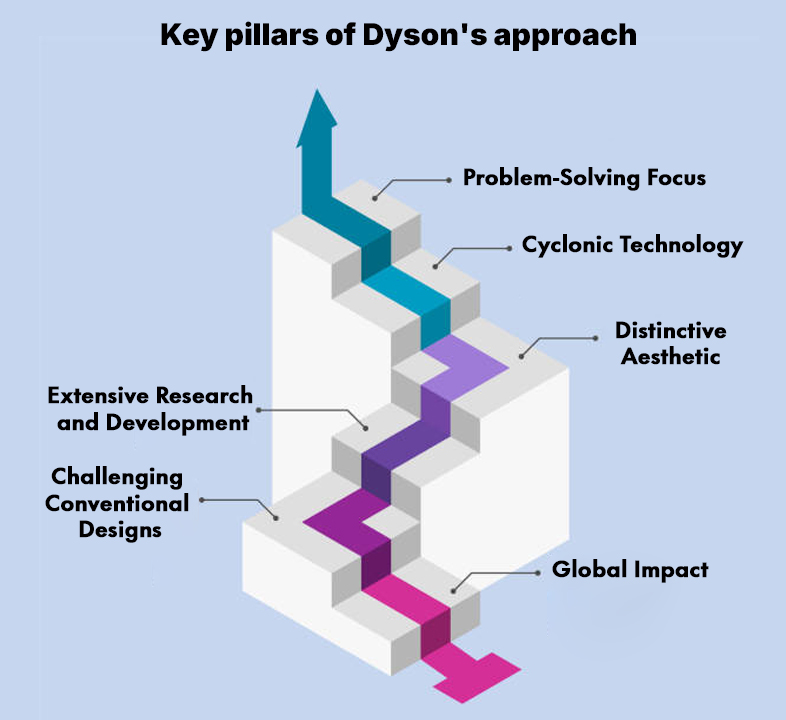

Key pillars of Dyson’s approach:

- Problem-Solving Focus: Dyson’s designs stem from a desire to improve upon existing products. James Dyson’s personal frustration with traditional vacuum cleaners losing suction led him to develop the cyclonic vacuum cleaner.

- Cyclonic Technology: The core of Dyson’s innovation is the use of cyclonic separation to eliminate the need for vacuum bags and maintain consistent suction power. This technology was inspired by industrial cyclone separators used in sawmills.

- Distinctive Aesthetic: Dyson products are often characterized by their transparent components, allowing users to see the inner workings and emphasizing the technology behind the design.

- Extensive Research and Development: Dyson invests heavily in research and development, pushing the boundaries of what’s possible in product design and engineering.

- Challenging Conventional Designs: Dyson’s products often challenge conventional designs and expectations, such as the bladeless fan and the Airblade hand dryer.

- Global Impact: Dyson’s products have gained worldwide recognition for their innovative design and performance, establishing the company as a global brand.

Dyson Design Process

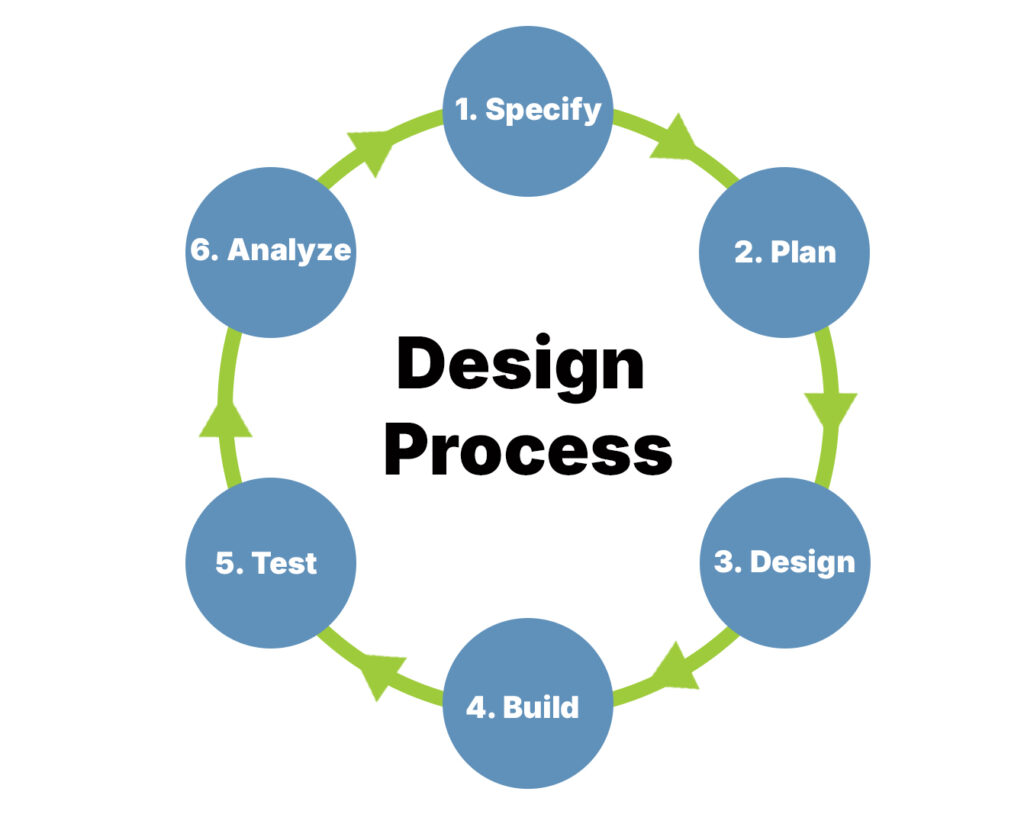

Dyson’s design process is rooted in solving real-world problems through engineering innovation. Each product goes through a rigorous journey from idea to execution, defined by six core stages:

1. Specify

Every project starts with a clear problem — like vacuums losing suction or unhygienic hand dryers. Engineers define a broad brief and develop a detailed product specification using the ACCESS FM criteria:

- Aesthetics: Look, feel, sound

- Cost: Manufacturing and retail price

- Customer: Target audience

- Environment: Environmental impact

- Safety: User protection

- Size: Appropriate dimensions

- Function: Usability and performance

- Materials Suitable and sustainable components

2. Plan

Dyson projects follow tight timelines with room for iteration. Milestones help keep development on track, ensuring ideas are tested and improved repeatedly.

3. Design

Engineers brainstorm and sketch ideas, turning concepts into rough visual forms. No idea is off-limits. Multiple iterations follow, often requiring hundreds or thousands of prototypes, as seen in Dyson’s first cyclonic vacuum.

4. Build

Early models are made from cardboard to test form and function. These evolve into CAD models and 3D-printed parts, which are assembled into working prototypes for further testing.

5. Test

Prototypes undergo extensive testing — often to failure. Engineers ensure products meet all specifications and survive real-life usage. If not, they go back, refine, and test again.

6. Analyze

The final stage, Engineering Build 1 (EB1), tests manufacturing quality and long-term durability. Any flaws found are addressed to refine both the product and the production process.

Innovation Centers

- Cotswolds campus: First R&D and manufacturing centre, birthplace of DC01.

- Imperial Robotics Lab: Pushing next-gen robotics and AI-driven machines .

- Dyson Institute (Wiltshire): Educates and employs undergrads pioneering new tech.

- Singapore HQ and motor plant: Built for global reach with cutting-edge electric motor mass production .

Milestones in Dyson’s Journey

The First Cyclonic Vacuum Cleaner

Dyson’s big breakthrough came with the DC01, the world’s first bagless vacuum cleaner using cyclonic separation. It wasn’t just a better vacuum—it was a complete rethink of how vacuums should work. It became the best-selling vacuum in the U.K. within two years of launch.

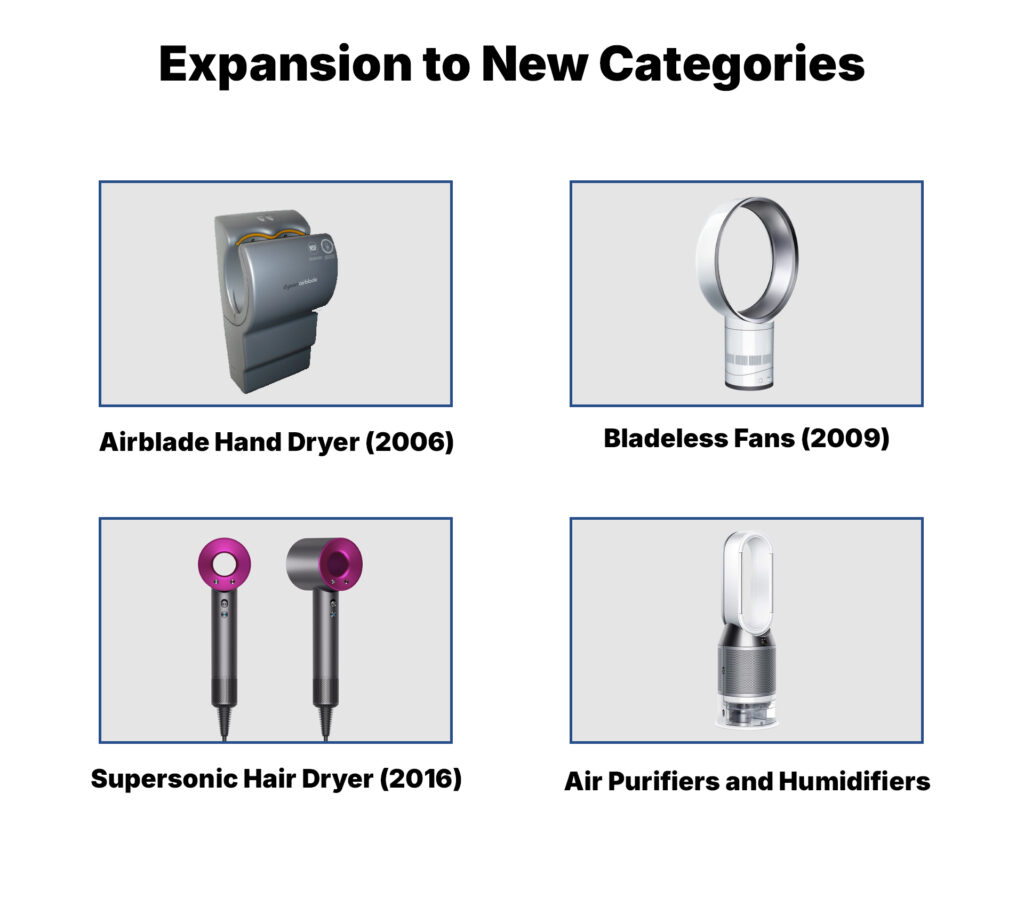

Expansion to New Categories

- Airblade Hand Dryer (2006): A radical rework of public hand dryers—hygienic, eco-friendly, and fast.

- Bladeless Fans (2009): Air Multiplier technology brought cooling without exposed blades.

- Supersonic Hair Dryer (2016): Dyson reinvented hair drying with high-speed motors, reduced heat damage, and futuristic design.

- Air Purifiers and Humidifiers: Clean indoor air became a Dyson mission with HEPA and carbon filter tech.

Entry Into Robotics and AI

Dyson began investing heavily in robotics, opening a specialized lab at Imperial College London and acquiring AI-focused companies. Its long-term goal? Smart, autonomous home helpers. The Dyson 360 Eye robot vacuum was an early result, but bigger ambitions remain in stealth mode.The Electric Car

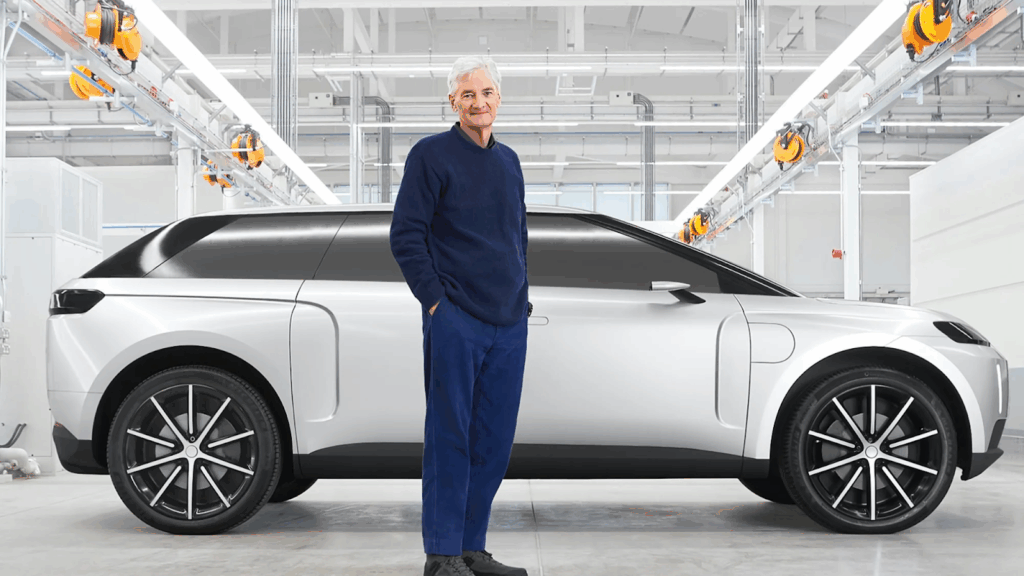

In 2017, Dyson shocked the world by announcing an electric vehicle program. Backed by £2 billion and housed in Hullavington Airfield, the project was ultimately scrapped in 2019 due to high costs and tough competition. Still, the research helped improve their motor and battery tech.

Top Dyson Products: Past, Present & Future

Past Icons

- G-Force (1983): Dyson’s first breakthrough, the G-Force vacuum, debuted in Japan with a luxe pink-steel finish—proving cleaning tools could be both innovative and aspirational.

- Airblade (2006): The Airblade hand dryer revolutionized hygiene with high-speed air that dried hands in 10 seconds—no paper, less energy, and more cleanliness.

- DC07 & DC14 (Early 2000s): These uprights introduced Root Cyclone™ tech, boosting suction and filtration—setting new industry standards.

- Dyson Ball (2005): Replaced wheels with a ball for unmatched maneuverability—reshaping vacuum design forever.

Present Bestsellers

- Dyson Robot Vacuum: A smart vacuum with real-time mapping, powerful suction, and a full-width brush bar. Uses SLAM navigation, adapts to layout changes, and can be controlled via the Dyson Link™ app.

- Dyson Pure Hot+Cool: A 3-in-1 device that heats, cools, and purifies. Features HEPA filtration, intelligent climate control, night mode, and voice control via Alexa, Google Assistant, and Siri.

- Dyson Purifier Big+Quiet: Built for large spaces, it uses a HEPA H13 filter and projects purified air over 10 meters. Captures 99.95% of pollutants, destroys formaldehyde, and provides real-time CO₂ monitoring.

- Dyson Supersonic Hair Dryer: Designed to prevent heat damage with a digital motor in the handle, magnetic attachments, and intelligent heat control. Quiet, balanced, and a favorite among stylists.

- Dyson Airwrap: A multi-styler that curls, smooths, and volumizes using the Coanda effect—no extreme heat. Beloved for versatile, hair-friendly styling.

- Dyson Cyclone V10 & V11: Top cordless vacuums before the V15, known for long battery life, strong suction, and multi-surface performance. Still widely trusted by users.

Future Innovation

- Robotics Expansion: Dyson announced plans to release more advanced home robots by 2030.

- Wearable Air Purifier/Headphones (Dyson Zone): Combining noise cancellation with air filtration—perfect for urban environments.

- AI-Powered Cleaning: Next-gen vacuums will adapt to floor types, dust levels, and room layouts in real time.

Recognition and Awards

Dyson’s influence goes far beyond groundbreaking engineering. Over the years, Dyson has received numerous accolades that reflect its values, mission, and growing impact worldwide.

- Forbes – World’s Best Employers (2023): Highlights Dyson’s focus on employee satisfaction, innovation, and global career growth.

- Forbes – Top Companies for Women (2023): Recognizes Dyson’s inclusive culture and support for women in leadership.

- The Times – Top 100 Graduate Employers (UK, 2023 & 2024): Acknowledges Dyson’s strong graduate programs and early-career opportunities.

- GradSingapore – Leading Graduate Employers (2023 & 2024): Celebrates Dyson’s appeal to top talent through innovative projects and cross-functional roles.

- Universum UK & Singapore (2024): Dyson ranks among the most attractive employers for students and professionals, thanks to its cutting-edge work and learning environment.

- D&I Award Japan (2024): Commends Dyson’s commitment to diversity and inclusive hiring in global markets.

- Employee Experience Awards Singapore (2023): Awarded for Dyson’s women leadership program, supporting gender equality and future female leaders.

Conclusion

From a lone inventor tinkering in a shed to a global design powerhouse, Dyson’s story is a testament to persistence, innovation, and obsession with perfection. The company didn’t just solve a problem—it turned everyday frustrations into opportunities for radical reinvention. Whether it’s revolutionizing vacuum cleaners, reimagining hand dryers, or developing AI-enabled appliances, Dyson keeps proving that thoughtful engineering can change the world.

What makes Dyson truly stand out isn’t just its cool tech or sleek aesthetics—it’s its relentless dedication to solving real problems in meaningful ways. And with billions being poured into robotics, AI, and sustainable technology, Dyson’s future looks even brighter.

Deepak Wadhwani has over 20 years experience in software/wireless technologies. He has worked with Fortune 500 companies including Intuit, ESRI, Qualcomm, Sprint, Verizon, Vodafone, Nortel, Microsoft and Oracle in over 60 countries. Deepak has worked on Internet marketing projects in San Diego, Los Angeles, Orange Country, Denver, Nashville, Kansas City, New York, San Francisco and Huntsville. Deepak has been a founder of technology Startups for one of the first Cityguides, yellow pages online and web based enterprise solutions. He is an internet marketing and technology expert & co-founder for a San Diego Internet marketing company.